Farmington

5-Star Epoxy Flooring of Farmington

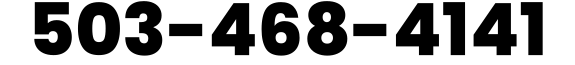

Reach us today for quality residential, business, and industrial epoxy coating service.

Epoxy Floor Coating Contractors in Farmington, Oregon

Epoxy flooring is fast becoming a popular option for protecting concrete floors.

A long lasting, low-maintenance finish that can be employed over numerous surfaces, it is easy to see why it has come to be so popular.

In fact, epoxy is swiftly becoming among the most popular technique for covering concrete in numerous domestic and industrial environments. Let’s have a look at a few of the benefits of epoxy floor finish.

First of all, epoxy floor finish is fantastic for protecting your floor against stains and spills. No matter if it’s from coffee drinks, soda pop, or a different liquid, spills are frequently hard to remove.

If they aren’t gotten rid of right away, then they can quickly permeate into the underlying concrete giving you a troublesome issue.

If you have an epoxy finish on your concrete, then stains can be quickly gotten rid of by merely clearing the location with a brush.

An additional benefit of epoxy floor finish is that it is non-scratch, dent, and chip resistant. Say goodbye to damaged tiles or razor-sharp edges.

If a spill occurs, simply wipe up the excess liquid rapidly and the location will be restored to its real appearance.

The epoxy sealant also provides a level of protection from uv rays. Sunshine can be extremely destructive to stained and painted concrete.

Farmington Epoxy Floor Coating Service

The numerous benefits of epoxy flooring:

There are numerous advantages to epoxy floor finish. If you are thinking about an epoxy application, then there is no more effective method to make certain that you get the best result possible.

Our qualified epoxy specialists will be able to offer advice on which types of resins are suitable for your particular circumstance, and this insight needs to be second only to the quality of the resins.

With proper planning, a great finish can last a very long period of time. There is no need to stress over moisture dripping in via a damaged floor. In addition, epoxy resins are fairly maintenance free.

As soon as employed, merely wipe up any spills or stains, and you’ll find no need to employ any additional products to ensure their sturdiness.

The benefits of epoxy finishings don’t end there. They can also reduce noise transmission through floors. The barrier produced by the finish can actually add to the sound reduction by making it tougher for them to go through the concrete.

This has the added benefit of making sounds dampening equipment like radon counters or sump pumps more reliable. These included benefits come at a slightly higher expense, however the outcomes far outweigh the extra expense.

The benefits of epoxy floor finish can go even farther than lowering sound and heat energy transmission. If you are trying to sell off your home or rent a home, the finish can also help to make your home more energy effective.

Less heat energy and less sound mean less electrical energy bills and less frustration when trying to sleep during the night. The finish not only provides protection to your floor from grime, but also from pests.

The benefits of epoxy floor finish don’t end there. If effectively employed, they can also create a non-slip surface area, make your home more protected, and boost the appearance of your home..

With such benefits as these, it’s easy to recognize why epoxy is becoming such a preferred floor covering choice. Now is the moment to find out more about the procedure of putting on an epoxy floor finish to help you decide if this is the appropriate option for you.

The very first thing we do prior to we begin any epoxy floor finish job is to remove any prevailing flooring and coverings. This includes moldings, insulation, and caulk. Often times we may utilize a rigid bristled brush or a power cleaner to remove the old finish and enable it to air dry..

It is very important that we enable adequate time for the older finish to entirely dry prior to putting on the new one.

Next, you will need to pick an epoxy floor finish set that will provide you the best outcomes. As soon as you have picked a set from us that fits your requirements the very first thing our people do is employ the new finish.

There are 2 separate methods to employ an epoxy floor finish. One method is to spray it on and enable it to set overnight, then paint over it; the other method is to simply employ it by hand.

Epoxy flooring is highly advantageous in household and business properties. Get In Touch With our Farmington epoxy flooring experts now for any concerns you have on epoxy finish.

EPOXY FLOOR FINISHING

If you are thinking about epoxy flooring, you will need to read this. You will find 5 methods how epoxy flooring makes your daily living easy..

This type of flooring is a strong protective finish that will save you cash, time, and energy on maintenance. The expense and effort in the past were massive.

Now, with simply a couple of basic methods and a little research, you can install a fantastic epoxy flooring system for a sensible rate.

When you take a look at epoxy flooring finishings, you will see the wide range of options available. There are numerous advantages to picking this type of flooring..

For example, if you have an older, scratched, or discolored floor, you will find that the resins can help to refresh and protect your floor..

This type of flooring is also very special due to the fact that it is made up of small beads and resins that fit together to create a strong, seamless floor.

One more reason that epoxy flooring is so attractive is that it is very easy to employ. Our expert installers are able to have the job completed in a timely manner and efficiently.

When you think of the maintenance of epoxy flooring, you will realize that it is quite easy to always keep it looking fantastic..

Given that you can seal the bead together, you will not need to stress over wetness getting in between the sealant and the surface area. If there is any moisture, the sealant will secure it together up until it dries out..

You can even utilize the sealant to protect the floor against spills from containers or food products. It is also easy to tidy up if a spill occurs, due to the fact that you do not need to clean off the dirt with a sponge.

If you would like to know how epoxy flooring makes your home more valued, then you should think of sealing off your floors..

When you seal the surfaces, you will find that they are a lot more long lasting than regular surfaces. They can handle a lot more abuse than common soft top floors..

This is a fantastic investment, and your home will look fantastic for several years to follow.

You may question why the home inspector has recommended epoxy flooring in your basement..

The sealant will offer extra protection to your home from mold, mustiness, insects, and any other unwanted material that can trigger damage to your floors..

The sealant will help prevent wetness from developing in between the concrete piece and the wood beams in your basement. In the absence of the sealant, the wood and concrete would bloat and rot..

This indicates that the sealant will make your basement a lot easier to preserve when compared to many other types of floors.

The sealant can offer a lot more protection than you believe. Sealants can protect your floor from deterioration caused by heat, chemicals, wetness, and so much more..

You do not need to stress over the health and wellness of your family when you utilize epoxy flooring. The sealant does not add a degree of poisonous chemicals to the air as a few other floor coverings do..

Epoxy surfaces are safe and will not trigger issues for people who are vulnerable to severe chemicals.

There is no need to spend thousands of dollars on a new basement floor when you can quickly get an epoxy floor..

Epoxy surfaces can be found in a range of color schemes so you can match your home’s décor. An epoxy floor can be produced with a mix of various resins to provide you a big variety of alternatives..

If you have apprehensions about how epoxy will operate in your home or business property, consult with our company right away.

We will help you pick the best possible services and designs for your epoxy flooring requirements.

GARAGE FLOOR SURFACE SEALING

If you are looking for the top flooring alternatives for garages, our crew will offer you with the info you need.

The garage is among the most important spaces in your home.

It is also among the most mistreated spaces. Therefore, it is important that you protect this valued storage room.

By picking the best flooring option possible, you can make last a long time without needing repair work completed frequently.

The leading alternatives for garages are epoxy flooring, Quikrete garage tile flooring, and natural stone flooring.

Many years of low maintenance and sturdiness make it a fantastic choice for numerous homes. It is immune to stains and has outstanding heat and moisture resistance properties.

It does not yellow quickly and shows off to its best potential when installed effectively. It is easy to clean with a power washer and a cleaning agent solution. It is an ideal choice for a moisture barrier.

The pros of these types of flooring include the truth that they need minimal maintenance and can take on any environment change..

They are also resistant to stains. This flooring item comes in a range of colors and styles..

A few of the pros of rubberized tile flooring include the truth that it is resistant to stains and heat..

It is easy to maintain, and comes in a series of various colors.

The primary downside regarding this type of flooring product is that it can be a bit pricier. This all depends on the design..

The benefits of epoxy sealed concrete flooring are that it includes a long life span, it is low maintenance and will need minimal to no upkeep in between 6 to 10 years.

As you can see from the aforementioned info, all these types of flooring are popular garage flooring alternatives..

You should do your research and identify which type would best suit your requirements. Your spending plan, the appearance of your garage, and the amount of traffic the garage experiences will all affect your decision..

In the long run, you will spend less cash on epoxy garage flooring than you will on costly repair work.

If you decide to utilize epoxy flooring, you will need to have it sealed.

Rubberized tiles are also favored however there are some drawbacks to these floors as well..

One drawback of rubberized tiles is that they are quickly harmed by acid-based cleaning solutions..

One more drawback of these floors is that they don’t stand up well to extreme temperature levels and dampness..

In the summer these tiles will become very hot and sticky and in the cold weather they will fracture and break..

Epoxy floors on the contrary are resistant to heat, wetness, and acid and they look fantastic all year long.

Our crew of experienced epoxy flooring professionals will give you a no-cost no-obligation price! Contact us now!

Our Epoxy Coating Work

EPOXY FLOORING RESTORATION AND FINISHING

If you have recognized an improvement in your floor or concrete driveway after employing an epoxy finish, you most likely also recognize a transformation in its appearance.

This will be in terms of its color, its shine, and even the amount of dust it takes on and takes off. However if you recognize modifications in your floor that aren’t related to its treatment, you may have a more major issue.

That issue is moisture content accumulation below the epoxy. This accumulation might be due to incorrect cleaning practices. Another is a much deeper issue like structural damages, that can trigger your epoxy floor finish to peel.

The reason this takes place is due to the fact that the base material, which is generally either polyurethane or Phenolic resins, is penetrable. When it’s applied to a solid surface area like concrete, its chemical bonds weaken and it’s empowered to gradually penetrate the surface area..

As soon as this has taken place, the epoxy leaks within the pores of the concrete and bonds chemically with the concrete itself. Then moisture vaporizes as it interacts with the epoxy. The procedure creates a physical barrier around the base of the floor that slows down any further motion.

Moisture vapor is the greatest issue with epoxy floor coatings. The chemicals bond so closely that the wetness rapidly takes in into the epoxy itself. Furthermore, when you put on the epoxy finish to your floor, you must utilize a special, reinforced floor scraper to remove it..

And due to the fact that there are many other microscopic dust debris, the scraper must be utilized thoroughly to stop the accumulation from progressing upward and damaging your floor.

Correct use of the floor scraper can help prevent your epoxy floor coatings from ending up being ineffective-and it doesn’t take a lot to make the coatings inefficient.

Correct Seal needed

Epoxy coatings can’t effectively seal if there are a lot of voids in the seal. These coatings also need to allow for expansion and shrinking during the lifespan of the building, so any spaces in the seal are a potential issue.

Sealing pores and fractures in epoxy coatings also boosts the danger of deterioration. The higher the surface area stress of the finish, the more probable it is to corrode in time..

If there are large spaces in the seal, the finish will not be as reliable in containing the deterioration. Of course, the bigger the surface area gap, the more damage the finish will have the ability to prevent. That’s why these coatings are only utilized on bigger floors.

Though epoxy floor coatings are very long lasting, they still have some maintenance requirements. New coatings must be applied every few years, especially in high traffic locations.

Some areas are susceptible to continuous traffic and requires to redo certain locations in time. This means that the finish may become brittle at the points where it is thinnest. The brittle locations can then crack and break, and all new stains and/or deterioration can then develop.

To conclude, though they are highly long lasting, they must be effectively maintained in time. They must also be effectively applied or installed. If the floor is not sealed properly, pollutants can build up below..

Newer products are making it easier to install properly, however if you recognize any issues with your floor, you should contact our qualified installers to make certain that the issue is addressed well before it worsens.

INDUSTRIAL GRADE EPOXY FOR COMMERCIAL LOCATIONS

Why pick industrial-grade epoxy for your business property?

Due to the fact that this option provides an outstanding collection of advantages as follows:

Boosted appearance: Your warehouse does not need a hip and stylish design. However, it needs to still look sharp nevertheless. Ease of maintenance and boosted appearance.

There is a common misunderstanding amongst the majority of people about epoxy floor coatings and their ability to boost the visual appeal of your space.

This misunderstanding is primarily due to the use of numerous chemicals in the concrete floor coatings. That is not the case. While the majority of people assume epoxy floor coatings are tough and long lasting, the fact is epoxy floor coatings are also highly versatile.

With proper maintenance and cleansing, you can ensure their extensive life and charm for a very long time. The chemical agents in concrete floor coatings diminish gradually in time, supplying an attractive surface area that stays crystal clear even after numerous years of continuous use.

How about their resilience?

As compared to other kinds of floor options, epoxy floor coatings supply a more irreversible solution. They are also weather-resistant, which ensures the resilience and safeness of your space.

Their elevated degree of resilience and safeness is made possible by employing only the right chemical mix which effectively seals the surface area while contributing to its stability.

Moreover, epoxy floor coatings are environment-friendly. They don’t add to the already-overloaded environmental pollution and hence help in reducing the negative impact on the ecosystem.

This in turn assists to protect and maintain the natural resources for a much longer period of time. If this procedure is effectively managed, it can substantially reduce the negative impact on the ecosystem. When utilized effectively, they can make your location a lot more energy efficient.

Why should you consider epoxy floor options?

The most obvious advantage is the long-term cost savings you can obtain from utilizing epoxy floor coatings. The majority of people only think of the initial setup expenses when carrying out a renovation.

The genuine expense, you’ll take on in the future will be the fading of the floorings and other related damages. When you utilize epoxy, you can reduce your total expenses up by essentially 50%.

The other popular advantage of making use of this sort of floor is that they offer outstanding flame protection. Many types of floor can quickly sustain fire and various other types need special fire-resistant materials or processes to ensure their resilience.

Did you know that this sort of floor is available in various kinds and colors? You can choose from a range of epoxy alternatives and add them in your location. By picking this material, you can save cash and time, which can lead you to higher revenue.

Aside from securing the floor from dirt and stains, epoxy also assists in avoiding wetness accumulation. This is due to the fact that the finish keeps your floor completely dry..

The epoxy coatings have the ability to attract wetness far from the surface area. At the same time, dirt and stains can not develop on the floor’s surface area any longer.

With its resilience, epoxy floor has the ability to endure extreme temperature levels. In reality, its resilience permits the floor to sustain extreme cold and heat for an extended period of time..

If you are preparing to put on this product to an industrial warehouse, you are guaranteed that it would last for several years.

There are numerous other benefits of employing epoxy in your industrial facility or warehouse. Besides being able to avoid wetness accumulation, the epoxy floor would also have the ability to boost its life expectancy..

The more time the epoxy floor remains protected, the much better it would work in keeping your warehouse well-maintained.

WHAT ARE THE DIFFERENT KINDS OF EPOXY FLOOR SURFACE COATINGS?

Epoxy Mortar Floors:

This epoxy floor is made up of 100% solid epoxies, graded and/or quartz sand. Mortar systems have the ability to manage a good deal of impact on the finish The benefits of using this type of epoxy floor is to help fix fractures prior to applying another type of epoxy floor.

Spaces to utilize epoxy mortar floorings: storage facilities, more business cooking areas, dining establishment environments, garages, and various manufacturing buildings.

Self-Leveling Epoxy Floor Surfaces:

This form is utilized to add over new, outdated, cracked, or harmed concrete floors. It assists with producing a resilient, leveled texture and smooth floor. These type of epoxy floors can be found in many different color options that function extremely well in commercial, industrial, and domestic spaces.

Greatest spaces to utilize self-leveling epoxy floor surfaces: storage facilities, huge display rooms, business garages, athletic centers, and in cooking areas as well.

Quartz-Filled Epoxy Flooring:

Quartz epoxy flooring is a combination of a high-performance epoxy polymer resin and colored quartz particles. Numerous business and property managers utilize this type of floor for decorative spaces that need hygienic and slip-resistant characteristics.

Common spaces to utilize quartz-filled epoxy floorings: bathrooms, schools, locker spaces, snack bars, foyers, and various display rooms.

Anti-Static Epoxy Coating (Electro-Static Charge Resistant Floors):

These type of epoxy floors help in reducing any static threats in any kind of work spaces. This is extremely important in locations and places which contain combustible components.

The best places to utilize anti-static epoxy floorings: any spaces that utilize combustible fuels or fluids, healthcare buildings, electronic, and chemical facilities.

Epoxy Flake Floors:

This type of epoxy floor includes colored flake materials. We insert them in the epoxy to produce a vibrant appearance. The flakes create a safe environment by helping in reducing any trips and falls.

Our epoxy flake floors can be found in a big range of dimensions, colors, designs, and textures. Our specialists can aid with customizing any size area you have.

Most ideal recommendations to utilize epoxy flake floorings: sports plex buildings, clinics, garages, and locker spaces.